Boron carbide is the most important raw material for making refractory materials

Release time:2020/07/30 Author:

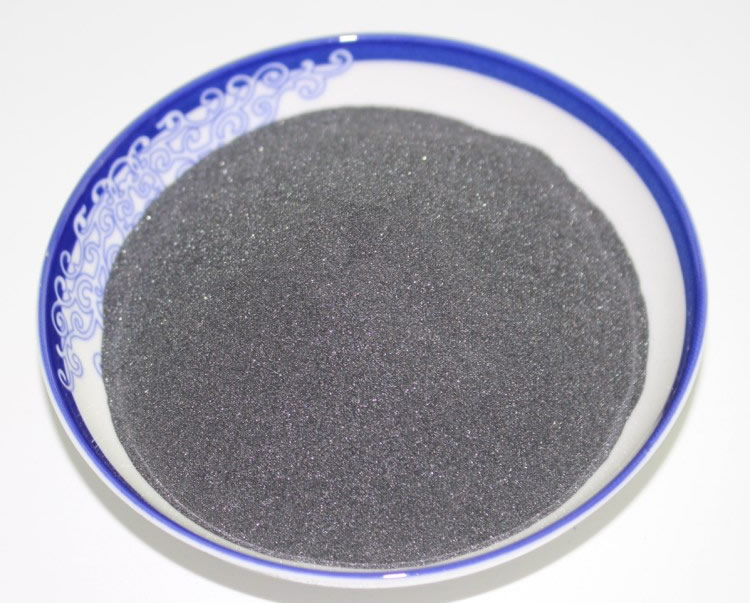

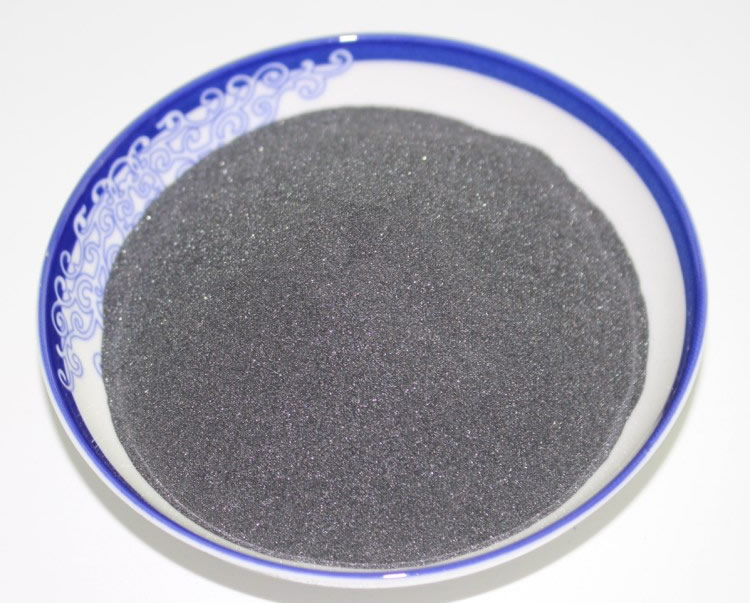

boron carbide b4c

Boron carbide is the most important raw material for making refractory materials

In industrial production, many materials must have the characteristics of high temperature resistance, and in the production process, boron carbide is one of the more important raw materials for the production of refractory materials.

Boron carbide has the properties of oxidation resistance and high temperature resistance. It is used as a high-grade shaped and unshaped refractory material and is widely used in various fields of metallurgy, such as steel stoves and kiln furniture. As the steel industry needs to save energy and reduce consumption and smelt low-carbon steel and ultra-low-carbon steel, the research and development of low-carbon magnesia-carbon bricks with excellent performance (general carbon content <8%) has attracted increasing attention from domestic and foreign industries. At present, the use of low-carbon magnesia-carbon bricks is generally improved by improving the bonded carbon structure, optimizing the matrix structure of magnesia-carbon bricks, and adding high-efficiency antioxidants. Among them, graphitized carbon black composed of industrial grade B4C and partial graphitized carbon black is used. Composite powder, using it as a carbon source and antioxidant for low-carbon magnesia-carbon bricks, has achieved good results.

Boron carbide plays an anti-oxidation effect in carbon-containing refractories, which can densify the product and prevent the oxidation of carbon in carbon-containing refractories. At the same time, it reacts at 1000°C to 1250°C to form columnar crystals distributed in the refractory matrix and gaps. In this way, the porosity is reduced, the medium temperature strength is improved, and the volume of the generated crystals expands, which can heal volume shrinkage and reduce cracks.

You may be interested in the following information?